Showcase – Homes NSW MMC Program

Experience the Future of Housing

Homes NSW, in collaboration with Building 4.0 CRC, presented the future of social housing at the Modern Methods of Construction (MMC) Showcase in Mascot, NSW. Visitors saw firsthand how our innovative ‘Kit-of-Parts’ system is transforming housing delivery.

The Showcase was an opportunity for visitors to:

- See a fully built, two-bedroom demonstration apartment

- Learn about improved quality, sustainability, and liveability in housing

- Engage with experts and industry leaders committed to solving the housing crisis.

Activities throughout September and October 2025 – the official Launch, industry workshops, an Open Day, private briefings and a Walk-Through – attracted over 1,000 attendees. You can read more below.

Homes NSW MMC Program: Solving the Housing Crisis

Background

The traditional method of housing construction, largely unchanged for a century, is too slow and costly to meet this growing demand.

In response, the NSW Government has committed a historic $6.6 billion investment aimed at constructing 8,400 new homes and repairing 30,000 existing dwellings. To maximise the impact of this investment, Homes NSW and Building 4.0 CRC have developed the Modern Methods of Construction (MMC) Program.

What is the MMC Program?

The MMC Program is a revolutionary approach to delivering social housing. By leveraging modern manufacturing techniques and digitally enabled processes, we create standardised building components offsite. These components are then assembled rapidly onsite, fundamentally shifting the traditional 80% onsite, 20% offsite construction model.

The MMC Program is not just about building faster, but also about improving tenant outcomes, reducing lifecycle costs, stimulating local manufacturing, and building homes that are durable, liveable, and future-ready. The project commenced in May 2024, with Homes NSW and Building 4.0 CRC each contributing $2 million, in addition to in-kind contributions. We have also partnered with universities such as Monash University and the University of Melbourne for this research.

Rather than think about building site by site or project by project, our research primarily aims to develop a systematic program for housing delivery. This approach encompasses a 360° view of housing: from design and development, through to construction, maintenance, and repair.

Starting with medium-density homes (4-6-storey buildings) and using the standardised kit-of-parts manufactured offsite (i.e., bathrooms, kitchens, balconies), these parts will be assembled onsite, employing systems and processes to meet tenant needs, speed up delivery, and unlock economic efficiencies.

The ‘Kit-of-Parts’ Approach

A Modular System for Scalable Impact

The Homes NSW MMC Program uses a Kit-of-Parts methodology: a pre-defined suite of movable building components (e.g., bathrooms, kitchens, balconies, etc.) manufactured offsite and assembled onsite. This system allows for flexibility in design while improving build speed, quality, and cost-efficiency. Not every part is made offsite; the system provides for around 20% of building works to enable every building to be ‘fitted’ to the specifics of its location. In the other 80%, every part is designed to fit together within a standardised assembly framework, forming homes that are adaptable yet easily repeatable.

How it works:

- Homes are designed using a set of movable, interchangeable parts e.g., Clip-on balconies, double-glazed windows, preset wall dimensions etc.

- These parts are manufactured by multiple suppliers across the state using the same materials and processes, and from the same specifications.

- Standardisation ensures compatibility, interoperability, and scalability.

- Parts are delivered to the building site and assembled according to the specific site conditions, environment, and client design preferences.

Benefits of the Kit-of-Parts Approach:

- Scalability & Efficiency

- Repeatable components manufactured in bulk enable faster build times and significant cost reductions

- Workforce Readiness

- Attracts a more diverse, skilled, and inclusive workforce to construction by simplifying complex onsite tasks

- Quality & Safety

- Controlled offsite fabrication improves quality control, waste reduction, and safety conditions

- Design Flexibility

- While components are standard, homes can still be tailored to site conditions, climate needs, and community preferences

- Lifecycle Consideration

- Products are designed for long-term maintenance, ease of replacement, and improved tenant experience

Core Objectives of the MMC Program

- Speed and Efficiency: Rapid construction timelines to urgently address housing shortages.

- Cost-Effectiveness: Reducing overall housing costs through scalable, efficient production.

- Quality Assurance: Higher quality control through offsite manufacturing.

- Sustainability: Environmentally responsible construction and durable housing designs.

- Tenant Satisfaction: Improved liveability, adaptability, and long-term maintenance.

What Building 4.0 CRC Are Focusing On

The MMC Showcase reflects the key pillars underpinning Phase One of the Homes NSW MMC Program. Our aim is to develop a repeatable, scalable model for social housing delivery by addressing three critical areas:

- Tenants, Land & Housing Types – We are identifying high-priority sites and tenant needs to inform a replicable design framework for medium-density housing (4–6 storey apartments). Our work includes site analysis and design-led urban principles to ensure buildings suit diverse communities, integrate into local environments, and align with Homes NSW’s future pipeline of projects.

- Product, Supply Chain & Platform – This stream develops the backbone of the MMC Platform by defining products and components for standardisation to form the kit-of-parts and building a standardised design and assembly system. The team is working with suppliers to test this system, ensuring repeatability and scale is achievable, and developing benchmarking metrics to quantify and test outcomes. The primary goal is to achieve economic efficiencies while attaining the design standards and product requirements set by Homes NSW.

- Change Management & Delivery Pathways – We are building a change framework to guide procurement, supply chain engagement, and industry upskilling to scale. This includes engaging with stakeholders to inform all stages of the Program, building a procurement process that is scalable and improves time and cost outcomes, and designing an education and training framework for upskilling on the new ways of building using MMC.

Strategic and Community Impact

The MMC Program delivers significant economic, social, and environmental benefits:

- Economic Growth: Stimulates local manufacturing, creating jobs and boosting regional economies.

- Cost Savings: Provides cost-efficient housing solutions, maximising the impact of public investments.

- Environmental Sustainability: Promotes sustainable construction practices and energy-efficient housing.

- Community Integration: Develops housing solutions that respect and enhance local community characteristics.

System 600

What sets the Homes NSW MMC Showcase apart is not just what you see onsite, but what sits behind the walls. This platform is powered by a rigorous, open-source framework of industrialised construction known as System 600. Rather than reinvent the wheel on every project, this system creates a repeatable backbone for high-quality, affordable housing delivered at scale.

System 600 is a standardised design and assembly system currently under development by the research team. This system specifies dimensions and configurations for components to ensure compatibility of assembly. It is based on a collaborative open-source, comprising parts supplied by various unrelated suppliers. The System manages the selection and use of parts with design and controls certain design parameters.

At its core:

- System 600 uses a 600mm x 600mm grid system to manage component sizing and interoperability.

- It minimises the number of unique SKUs required, simplifying supply logistics and improving scale economies.

- Smart interfaces make onsite assembly intuitive and interchangeable across suppliers.

- Components can be delivered in multiple formats: individually, as subassemblies, or in large pre-built modules.

- Construction sequences are reimagined through decoupling and recoupling, improving efficiency in material and service installation.

The System Behind the Showcase

The Technical Expertise Powering MMC

What makes the Homes NSW MMC Showcase more than just a physical demonstration is the system that forms the backbone of design logic, manufacturing coordination, and scalable delivery. This system ensures that the demonstrator apartment is not a one-off build. It’s a replicable solution capable of delivering thousands of homes using standardised components and modular processes.

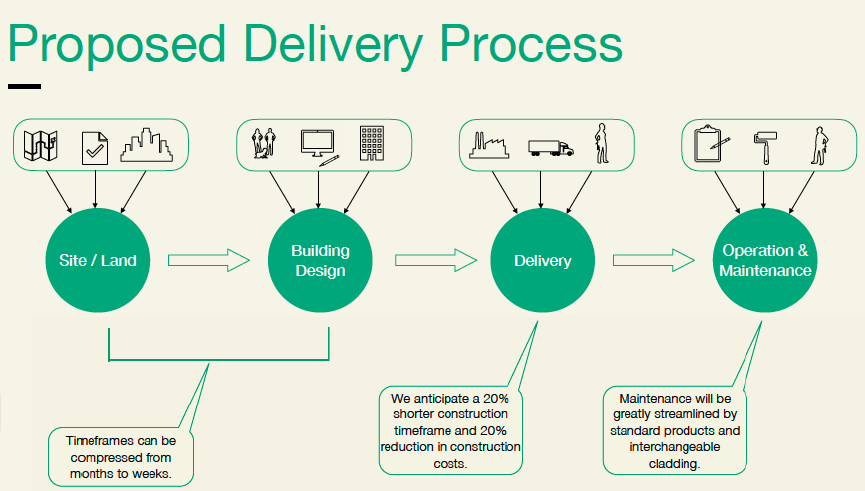

At the heart of the system is a set of principles that underpin every step of the build process, from early planning to onsite assembly and long-term maintenance. The MMC Program compresses traditional timelines and reduces costs by applying a consistent, staged delivery process to streamline how housing is planned, designed, delivered, and maintained.

Courtesy of Prof. Mathew Aitchison

This four-stage pipeline replaces traditional project-by-project builds with a repeatable system: shortening timelines, reducing costs by 20%, and simplifying long-term maintenance with interchangeable parts.

Glossary

- 3D Printing

- A construction method that utilises large scale 3D printers to create buildings layer by layer using cement style materials, sometimes referred to as ‘contour crafting’.

- AI (Artificial Intelligence)

- The simulation of human intelligence in machines, enabling automated decision-making and analysis in construction processes, enhancing efficiency and accuracy.

- Assembly

- The process of putting together prefabricated components or modules in factories or in assembly locations near or at the building site prior to final installation in a building.

- BIM (Building Information Modelling)

- A digital representation of the physical and functional characteristics of a building providing a shared knowledge resource for information about the facility throughout its lifecycle.

- Cassette

- A panel comprised of several flat layers, forming a thin box-like assembly. This may be used for floors or ceilings, which can be prefabricated with various services integrated into them before being transported to the site.

- Circularity

- Designing products with the entire lifecycle in mind therefore promoting reuse, recycling, and sustainability. Circularity encourages designers and manufacturers to consider the end-of-life phase during the design process, leading to less waste and more sustainable practices.

- CLT (Cross-Laminated Timber)

- An engineered wood product made from layers of timber boards with each layer glued together at right angles to the layer below. CLT is used for constructing walls, floors, and roofs, offering strength and sustainability benefits.

- Components

- Individual elements or sections of a larger system or structure often prefabricated offsite.

- Continuous Improvement

- An ongoing process aimed at enhancing work practices, products, services or designs through incremental changes over time. A systematic approach that encourages organisations to seek small, regular improvements by routinely reviewing and identifying areas where improvements and efficiency gains can be achieved throughout the life cycle.

- Creative Commons License

- A type of license that allows creators to share their work legally while specifying how others can use it, often used in the context of open-source designs and documentation in construction.

- Demountable

- Describes structures designed to be easily disassembled or relocated without significant loss of integrity or functionality.

- DfMA (Design for Manufacturing and Assembly)

- A design approach focused on simplifying the manufacturing and assembly processes. By considering the ease of assembly during the design phase, companies can reduce production costs and time while improving product quality. DfMA emphases minimising the number of parts and designing parts that are easy to assemble.

- DfMAD (Design for Manufacture and Assembly with Disassembly)

- An extension of Design for Manufacturing and Assembly (DfMA) design philosophy that facilitates the easy disassembly of building components at the end of their life cycle. This approach supports sustainability and circularity through recycling and reusing materials.

- Digital Twins

- 3D virtual replicas of physical assets, processes or systems that can be used for simulations, monitoring and analysis to optimise performance and maintenance in buildings.

- Fabricate

- The process of making building components or materials in a controlled environment, typically offsite.

- Flat-pack

- A delivery and assembly method where building components are designed to be produced in flat sections for transport. Flat-pack is another term for panelised systems where the elements of walls and ceilings are made of thin panels/cassettes as distinct from volumetric modular systems where a component is a box shaped volume with room like proportions. Flat-pack reduces costs and space requirements during transportation compared to volumetric modular.

- Glulam (Glued Laminated Timber)

- A type of engineered wood product made by bonding together individual pieces of lumber with durable adhesives. Glulam is used for structural applications due to its high strength-to-weight ratio and is mostly used for constructing beams or columns. Unlike Cross Laminated Timber the layers are glued parallel to their adjacent layers.

- Hybrid (Modular Hybrid)

- A construction approach that combines flatpack /panelised systems with volumetric modular components to enhance flexibility and efficiency in the building process. For example panelised walls and floors might be combined with volumetric bathroom module assemblies.

- IDC (Industrialised Design and Construction)

- A systematic approach to construction that integrates design manufacturing and assembly processes to improve efficiency, quality and sustainability in building projects.

- Installation

- The process of placing and fixing parts / assemblies / modules into the building site to form a complete building.

- Kit-of-parts

- A collection of pre-manufactured components that can be assembled onsite to create a complete structure. The kit exists prior to project design commencing, allowing a designer to choose the parts to comprise the design from.

- Lean Construction

- A methodology that focuses on minimising waste and maximising value in construction processes through efficient project management and continuous improvement practices. This is derived from lean manufacturing, often referred to as the Toyota Way. All forms of waste (material, motion, inventory, waiting, over-production, over-processing and transport) are constantly reviewed for improvements.

- Mass Timber

- Refers to heavy engineered timber products used in construction, including CLT, LVL and glulam. Mass timber is recognised for its sustainability, aesthetic appeal, and structural capabilities. The term heavy is relative to the lightweight nature of traditional timber house framing.

- MMC (Modern Methods of Construction)

- An umbrella term encompassing various innovative construction techniques aimed at improving efficiency, sustainability, and quality in building projects. MMC includes panelised construction, modular construction, kit-of-parts, prefabrication, and other advanced construction methods.

- Modular

- Describes a construction method where buildings are created using separate sections or modules that can be easily assembled. Correctly defined, the term is ‘volumetric modular’ and refers specifically to a box-like assembly. The term is often corrupted to refer to all forms of prefabricated systems including panelised systems.

- Modularisation

- A construction approach that involves creating pre-engineered sections or modules of a building in a factory setting, which are then transported to the site for assembly.

- Offsite

- Construction activities conducted away from the final building site, typically in a factory setting. Offsite methods enhance quality control, reduces waste and reduce onsite labour requirements. Offsite can include near site locations, for example adjacent vacant sites used as assembly facilities.

- Offsite Manufacturing

- Manufacturing focused specifically on the production of building components in a factory setting before transporting them to the construction site.

- Onsite Manufacturing

- Capability created at the building site to manufacture components that are then lifted into the building structure and installed. There are numerous examples of onsite manufacturing including site assembly of permanent formwork systems, robotics equipment in temporary sheds for making steel or timber elements and 3D printing, where the robotic equipment operates at the building site.

- Panelised Systems

- A construction technique involving the use of flat panels (such as walls or roofs) that are prefabricated offsite and then assembled onsite. A panel system may incorporate linings, pre-wiring, windows and doors assembled at a factory. This method allows for quick assembly. Panels are flat building elements, typically relatively thin in width. They may be described as Open or Closed depending on whether they are fully enclosed on both sides (closed) or one side has been left off (open) for purposes of inspection, installation access or to allow incorporation of other building works such as electrical services. Examples of panelised systems include CLT (Cross Laminated Timber), structural insulated panels (SIP), precast concrete, pre-nailed timber frames and unitised metal framing systems. Panels and cassettes are similar in nature. A cassette is a type of panel that incorporates several layers either side of a void. A panel can consist of a single layer, for example a panel of CLT.

- Parametric Design

- A design process that uses algorithms to manipulate design variables dynamically, allowing for rapid iterations and customisations based on specific requirements. This may also be referred to as computational design and sometimes as generative design where the algorithms are sufficiently sophisticated to cause part of the design to generate automatically in response to basic inputs.

- Part

- A simple discrete element of a building such as a beam, door or floor. The terms part and component are interchangeable. This is distinct from a raw building material like timber or plasterboard in that value has been added in the form of shaping, finishing, assembling or otherwise processing raw materials to create the discrete part. The term part further implies that the element can be separated from the rest of the building assembly and therefore made separate from the remainder of the building. This is distinct from, for example, a concrete structure where all of the columns and floors may have been poured as one cohesive mass that cannot be broken into parts.

- Pod

- Volumetric modules used in construction such as bathroom, kitchen or office pods which are manufactured offsite and installed within the main structure. Pods are typically not loadbearing structures and therefore still require the building to have a structural frame unrelated to the pod.

- Prefabrication

- Manufacturing parts offsite before transporting them to the construction site. This approach minimises onsite labour and reduces site based construction time while enabling high-quality standards in more efficient working environments. Key benefits include reduced construction costs through economies of scale and enhanced safety due to limiting onsite environment conditions. Prefabrication is a wide term for many different types of fabrication including basic traditional construction methods (performed offsite) to advanced manufacturing using automated equipment.

- Product Platform

- A framework or system that allows for the efficient design and production of multiple buildings using a common set of components or modules. This approach enhances standardisation, continuous improvement, compatibility and reusability across different projects. Central is the idea that the building is a product for a defined customer segment and that the platform ensures efficient production and achievement of product goals such as customer satisfaction, quality and value for money.

- SIP (Structural Insulated Panel)

- A composite building panel made from an insulating foam core sandwiched between two structural facings. SIPs provide insulation and structural integrity while allowing for quick assembly. SIPs are typically loadbearing elements with a capacity to achieve buildings 2-3 storeys in height.

- Site Assembly

- Site assembly or land assembly is the process of combining two or more small adjacent properties into a single, consolidated parcel.

- Stackable

- Refers to building components designed to be easily stacked or arranged vertically, facilitating efficient transportation and assembly on site.

- Standardisation

- The process of establishing uniform specifications and criteria for materials, components, and construction methods to ensure consistency, quality, and efficiency.

- System 600

- System 600 is being developed by Building 4.0 CRC’s research team as part of the Homes NSW MMC Program. It is a standardised design and assembly system used in modular construction that specifies dimensions and configurations for components to ensure compatibility of assembly. System 600 is an open-source, collaborative system comprising of parts supplied by various unrelated suppliers. The “600” of the title references the base 600mm x 600mm grid that coordinates the system’s internal planning.

- Traditional Construction

- A customised building with little to no offsite manufacturing. This construction method is considered the standard for most residential, commercial and industrial builds. Trade skills are required to interpret design intent into highly specific arrangements and to handcraft building materials into the final building configuration.

- Transportable

- Refers to a building that is entirely manufactured offsite and transported onsite. e.g. a small house that gets transported on the back of a truck.

- Quality Control

- A systematic process aimed at ensuring that construction outputs meet specified requirements and standards. Quality control involves monitoring all stages of the construction process, from material selection to final inspections.

- Volumetric

- Modular units that are three-dimensional and often include complete internal fittings (e.g., bathrooms or kitchens). These units are manufactured offsite and assembled onsite to form a complete structure.

FAQs

Modern Methods of Construction is an umbrella term encompassing various innovative construction techniques aimed at improving efficiency, sustainability and quality in building projects.

It is not a singular approach, rather it is a collection of methods to plan, design, build and maintain homes. MMC includes offsite manufacturing which can take many forms, for example, a kit-of-parts approach, modular, prefabrication and volumetric building.

MMC is not a new concept, with many home building products already built offsite including frames and trusses. Australia has deep expertise and innovation locally to be harnessed and grown.

To scale the adoption of MMC to maximise time and cost savings and deliver quality social housing faster, the Program is developing standardised and repeatable systems using consistent products manufactured offsite.

MMC can also be referred to as ‘industrialised construction’.

It is anticipated that the approach taken by the Homes NSW Program will reduce construction timeframes and costs by 20%. This estimate is based on the learning effects of increased production as well as global case studies. Savings are expected to increase over time as implementation is scaled up. These benefits are realised by using standardised parts and systems to achieve greater efficiencies than those possible when a project-by-project approach to design and construction is employed.

Scaling up demand and manufacturing of larger batches of parts is critical to growing the cost and time savings achievable while continuously improving quality.

Maintenance timeframes and costs are also expected to be reduced. Consideration of a home’s maintenance over its lifecycle will be at the forefront of any delivery. This includes ensuring that standard products can be sourced from multiple suppliers and easily installed to minimise disruption to tenants and improve productivity.

When it comes to using MMC to deliver housing, there is not a one size fits all solution. Any approach selected must address the problem at hand.

This is why our team has started by developing a holistic understanding and assessment of the diverse needs of Homes NSW.

These needs focused on the delivery of a large number of durable, adaptable and ‘tenure blind’ homes across NSW (indistinguishable from other housing in the market), in different locations and on both urban and regional sites.

Following this needs assessment, the research team reviewed key learnings from international and local case studies and how these would apply to the Homes NSW context.

Based on this comprehensive assessment and research, our team identified the kit-of-parts as the most effective MMC approach for the Homes NSW Program given its flexibility to adjust to local conditions. With products manufactured offsite and assembled onsite, this approach employs standard systems and processes which can be applied to build homes on a range of sites and locations.

The kit-of-parts allows efficient design, quality maintenance over lifecycle and most importantly, configuration to meet the evolving needs of different tenant cohorts.

This also means that Homes NSW would be able to source standardised products from multiple suppliers and create scale which drives a reduction in costs and an increase in quality.

The Program is focused on the kit-of-parts being sourced from a distributed supply chain with parts bought from a number of manufacturers. The Program proposes to draw on the latent manufacturing capability in the supply chain.

This approach will mitigate risk by working with a number of suppliers and reduce the need for high capital investment into purpose-built facilities. It will allow for wider participation, specialisation and leveraging of existing manufacturing capability. This is supported by an assessment of the capability and capacity of Australian based manufacturers.

For MMC to work, there must be commitment to use the define standardised parts, design and assembly systems.

There are previous examples where new product designs were added on a project-by-project basis. This led to an undermining of the scale of efficiencies and the principles of MMC.

For MMC to succeed and achieve the economic benefits available, there must be a consistency of solutions, standardised parts, designs that leverage a basket of standardised parts and a volume of procurement from a distributed supply chain.

This why the Homes NSW MMC Program is developing strategies, methods and frameworks for MMC to succeed, scale up and be adopted more broadly across the industry.

Building 4.0 CRC brings an independent and expert team of researchers to develop solutions to deliver quality social housing in NSW faster.

Each member of the team brings experience in their specialist area whether in design, manufacturing, procurement, supply chain management, stakeholder engagement, or education to the Program. This expertise is backed up by applied knowledge in using MMC across projects in Australia and New Zealand.

The CRC team is working closely with Homes NSW to incorporate learnings and best practice into the Program. This valuable involvement will leverage the CRC’s experience from their own projects, including the 70 CRC projects (either completed or active) undertaken since 2020 to revolutionalise the way we buil